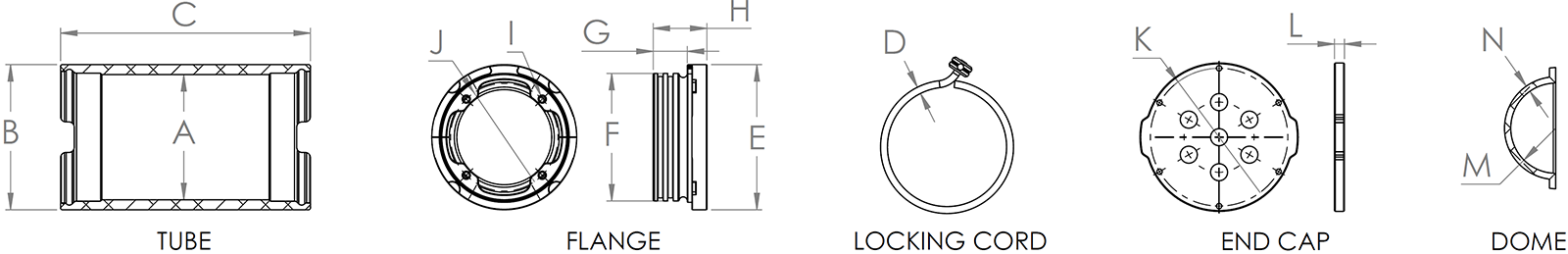

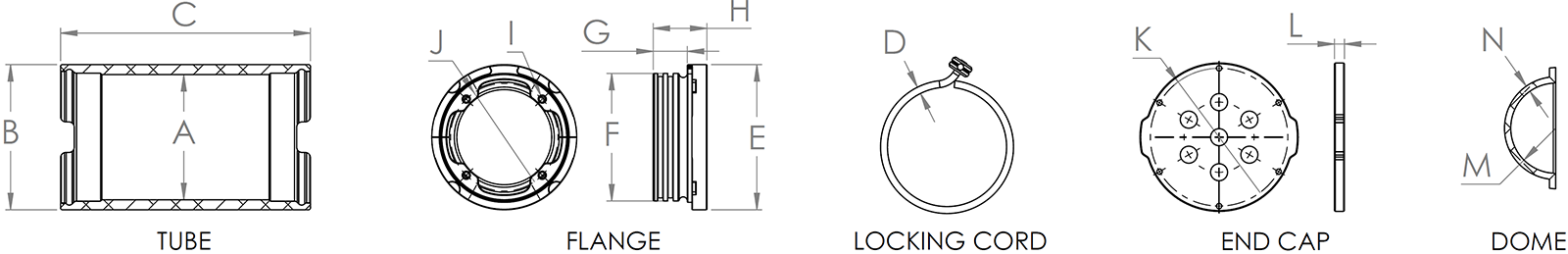

Specifications

End Caps

Domes

HS Codes

3D Models

2" Series

WTE2-P-END-CAP-R2 (.zip)

WTE2_FLANGE_CAP_RAILS_BLANK_BR-100276-999 (.zip)

WTE2_FLANGE_CAP_RAILS_2xM10_BR-100276-002 (.zip)

WTE2_FLANGE_CAP_RAILS_4xM10_BR-100276-004 (.zip)

WTE2_FLANGE_CAP_RAILS_1xM10_8xM6_BR-100276-009 (.zip)

WTE2-P-DOME-R1 (.zip)

WTE2-P-RETAINING-RING-R1 (.zip)

3" Series

WTE3_END_CAP_ACRYLIC_BLANK_BR-100949-998 (.zip)

WTE3-M-END-CAP-R1 (.zip)

WTE3-M-END-CAP-4-HOLE-R1 (.zip)

WTE3-M-END-CAP-7-HOLE-R1 (.zip)

WTE3-P-DOME-R1 (.zip)

WTE3-P-RETAINING-RING-R1 (.zip)

4" Series

WTE4_END_CAP_10xM10_BR-102993-002 (.zip)

WTE4_END_CAP_18xM10_BR-102993-003 (.zip)

WTE4_END_CAP_4xM14_1xM10_BR-102993-004 (.zip)

WTE4_END_CAP_5xM10_BR-102993-005 (.zip)

WTE4_END_CAP_8xM14_2xM10_BR-102993-006 (.zip)

WTE4_END_CAP_8xM14_7xM10_BR-102993-007 (.zip)

WTE4_END_CAP_ACRYLIC_BLANK_BR-102993-998 (.zip)

WTE4_END_CAP_BLANK_BR-102993-999 (.zip)

WTE4-P-DOME-R4 (.zip)

WTE4-P-DOME-RETAINING-RING-R1 (.zip)

5" Series

WTE5_END_CAP_BLANK_BR-102203-001 (.zip)

WTE5_END_CAP_5xM14_5xM10_BR-102203-002 (.zip)

WTE5_END_CAP_10xM14_7xM10_BR-102203-003 (.zip)

WTE5_END_CAP_26xM10_BR-102203-004 (.zip)

WTE5_DOME_AND_RETAINING_RING_BR-102597 (.zip)

6" Series

WTE6_END_CAP_BLANK_BR-102205-001 (.zip)

WTE6_END_CAP_5xM14_5xM10_BR-102205-002 (.zip)

WTE6_END_CAP_16xM14_13xM10_BR-102205-003 (.zip)

WTE6_END_CAP_15xM10_BR-102205-004 (.zip)

WTE6_END_CAP_5xM10_BR-102205-005 (.zip)

WTE6_END_CAP_BLANK_BR-102205-006 (.zip)

WTE6_END_CAP_ACRYLIC_BLANK_BR-102205-007 (.zip)

WTE6_END_CAP_12xM14_12xM10_BR-100140 (.zip)

8" Series

WTE8_END_CAP_BLANK_BR-102206-001 (.zip)

WTE8_END_CAP_5xM10_5xM14_BR-102206-002 (.zip)

WTE8_END_CAP_10xM10_10xM14_BR-102206-003 (.zip)

WTE8_END_CAP_14xM10_16xM14_BR-102206-004 (.zip)

WTE8_END_CAP_5xM10_BR-102206-005 (.zip)

WTE8_END_CAP_BLANK_BR-102206-006 (.zip)

WTE8_END_CAP_ACRYLIC_BLANK_BR-102206-007 (.zip)

Revision History

5 February 2025

- BR-100276-009, 50 mm (2") Flange Cap 1x M10 8x M06 – Initial release

20 January 2025

- BR-100276-999, 50 mm (2") Flange Cap Blank

- Updated to type III anodizing

- Added alignment holes for RAILS compatibility

- Widened pry slots

- 2x pry tools added to contents

- BR-100276-002, 50 mm (2") Flange Cap 2x M10

- Updated to type III anodizing

- Added alignment holes for RAILS compatibility

- Widened pry slots

- 2x pry tools added to contents

- BR-100276-004, 50 mm (2") Flange Cap 4x M10

- Updated to type III anodizing

- Added alignment holes for RAILS compatibility

- Widened pry slots

- 2x pry tools added to contents

15 January 2025

- All acrylic end cap tolerances updated

- BR-102993-998, 100 mm (4") Acrylic Blank – Depth rating decreased from 500 m to 300 m

- BR-100094, 50 mm (2") Acrylic Blank – Depth rating decreased from 600 m to 500 m

20 December 2024

- BR-102205-001, 150 mm (6") Blank – Updated to type III anodizing

28 October 2024

- BR-100273-001, 150 mm (6") 15x M10 part number changed to BR-102205-004

- BR-100273-002, 150 mm (6") 5x M10 part number changed to BR-102205-005

- BR-100273-003, 150 mm (6") Blank part number changed to BR-102205-006

- BR-100273-004, 150 mm (6") Acrylic Blank part number changed to BR-102205-007

- BR-101065-001, 200 mm (8") 5x M10 part number changed to BR-102206-005

- BR-101065-002, 200 mm (8") Blank part number changed to BR-102206-006

- BR-101065-003, 200 mm (8") Acrylic Blank part number changed to BR-102206-007

24 October 2024

- BR-100170, 100 mm (4") 10x M10 part number changed to BR-102993-002

- BR-101113, 100 mm (4") 18x M10 part number changed to BR-102993-003

- BR-100138, 100 mm (4") 4x M14 1x M10 part number changed to BR-102993-004

- BR-100875, 100 mm (4") 5x M10 part number changed to BR-102993-005

- BR-100066, 100 mm (4") 8x M14 2x M10 part number changed to BR-102993-006

- BR-100151, 100 mm (4") 8x M14 7x M10 part number changed to BR-102993-007

- BR-100061, 100 mm (4") Acrylic Blank part number changed to BR-102993-998

- BR-100184, 100 mm (4") Blank part number changed to BR-102993-999

- BR-100273-001, 150 mm (6") 15x M10 depth rating increased to 150 m

- BR-100273-002, 150 mm (6") 5x M10 depth rating increased to 150 m

- BR-100273-003, 150 mm (6") Blank depth rating increased to 150 m

- BR-100273-004, 150 mm (6") Acrylic Blank depth rating increased to 150 m

- BR-101065-001, 200 mm (8") 5x M10 depth rating increased to 75 m

- BR-101065-002, 200 mm (8") Blank depth rating increased to 75 m

- BR-101065-003, 200 mm (8")Acrylic Blank depth rating increased to 75 m

23 October 2024

- BR-100630, 75 mm (3") Acrylic Blank part number changed to BR-100949-998

7 February 2024

- BR-102203-001, 130 mm (5") Blank - Initial release

- BR-102203-002, 130 mm (5") 5x M14 5x M10 - Initial release

- BR-102203-003, 130 mm (5") 10x M14 7x M10 - Initial release

- BR-102203-004, 130 mm (5") 26x M10 - Initial release

- BR-102205-001, 150 mm (6") Blank - Initial release

- BR-102205-002, 150 mm (6") 5x M14 5x M10 - Initial release

- BR-102205-003, 150 mm (6") 16x M14 13x M10 - Initial release

- BR-102206-001, 200 mm (8") Blank - Initial release

- BR-102206-002, 200 mm (8") 5x M14 5x M10 - Initial release

- BR-102206-003, 200 mm (8") 10x M14 10x M10 - Initial release

- BR-102206-004, 200 mm (8") 16x M14 14x M10 - Initial release

14 July 2023

- WTE4-M-END-CAP-4XM14-1XM10-R1-RP SKU changed to BR-100138

- WTE4-M-END-CAP-8XM14-2XM10-R1-RP SKU changed to BR-100066

- WTE4-M-END-CAP-8XM14-7XM10-R1-RP SKU changed to BR-100151

14 June 2023

- WTE4-P-END-CAP-BLANK-R1 SKU changed to BR-100061

- WTE4-P-DOME-R4-RP SKU changed to BR-100495

- WTE4-M-END-CAP-BLANK-R2-RP SKU changed to BR-100184

- WTE4-M-END-CAP-10XM10-R2-RP SKU changed to BR-100170

- WTE4-M-END-CAP-18XM10-R2-RP SKU changed to BR-101113

8 June 2023

- WTE3-P-END-CAP-R1-RP SKU changed to BR-100630

- WTE3-P-DOME-R1-RP SKU changed to BR-101059

- WTE3-M-END-CAP-R1-RP SKU changed to BR-100949-999

- WTE3-M-END-CAP-4-HOLE-R1-RP SKU changed to BR-100949-004

- WTE3-M-END-CAP-7-HOLE-R1-RP SKU changed to BR-100949-007

1 June 2023

- WTE2-P-END-CAP-R2-RP SKU changed to BR-100094

- WTE2-P-DOME-R1-RP SKU changed to BR-100859

1 June 2023

- WTE2-M-LOCKING-FLANGE-CAP-BLANK-R2-RP SKU changed to BR-100276-999

- WTE2-M-LOCKING-FLANGE-CAP-2-HOLE-R2-RP SKU changed to BR-100276-002

- WTE2-M-LOCKING-FLANGE-CAP-4-HOLE-R2-RP SKU changed to BR-100276-004

10 March 2023

- WTE4-M-END-CAP-BLANK-R2 - Initial release

- Redesigned for increased depth rating

27 February 2023

- WTE4-M-END-CAP-10XM10-R2 - Initial release

- Redesigned for increased depth rating

20 December 2022

- WTE4-M-END-CAP-4XM14-1XM10-R1 - Initial release

- WTE4-M-END-CAP-8XM14-2XM10-R1 - Initial release

- WTE4-M-END-CAP-8XM14-7XM10-R1 - Initial release

- WTE4-P-END-CAP-R1 - Minor revision

- SKU changed to WTE4-P-END-CAP-BLANK-R1

29 November 2022

- WTE4-M-END-CAP-18-HOLE-R2 - Minor revision

- SKU changed to WTE4-M-END-CAP-18XM10-R2

19 November 2019

- WTE2-M-LOCKING-FLANGE-CAP-BLANK-R1 - Initial release

- WTE2-M-LOCKING-FLANGE-CAP-2-HOLE-R1 - Initial release

- WTE2-M-LOCKING-FLANGE-CAP-4-HOLE-R1 - Initial release

- WTE2-P-END-CAP-R2 - Initial release

- WTE2-P-DOME-R1 - Initial release

13 November 2018

- WTE4-M-END-CAP-18-HOLE-R2 - Initial release

20 April 2018

- WTE4-P-DOME-R4 - Initial release

27 December 2017

- WTE3-P-DOME-R1 - Initial release

28 December 2016

- WTE4-M-END-CAP-5-HOLE-R1 - Initial release

- WTE3-M-END-CAP-7-HOLE-R1 - Initial release

17 March 2016

- WTE3-M-END-CAP-4-HOLE-R1 - Initial release

- WTE3-M-END-CAP-R1 - Initial release

29 Jan 2016

- WTE4-M-END-CAP-14-HOLE-R1 - Initial release

13 November 2015

- WTE4-M-END-CAP-R1 - Initial release

24 September 2015

- WTE3-P-END-CAP-R1 - Initial release

1 September 2015

- WTE4-M-END-CAP-10-HOLE-R1 - Initial release

31 March 2015

- WTE4-P-END-CAP-R1 - Initial release