Jobs at Blue Robotics

Working at Blue Robotics offers many opportunities to grow professionally while contributing to our mission.

We are an equal opportunity employer offering competitive pay, benefits, and perks.

Term: Fall 2025

Start Date: September 2nd, 2025

Deadline to apply: July 31st, 2025

Hours per week: Minimum 40 hours

Duration: 4 or 8 months

Pay rate: $25 CAD – $35 CAD per hour

Location: Victoria, BC

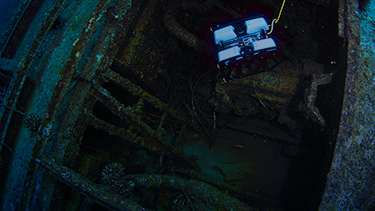

At Blue Robotics, we enable the field of marine robotics with affordable components and systems. What does this really mean? We design cool tech for use underwater that enables tons of people and organizations to pursue their audacious dreams of exploring and learning about our oceans and waterways.

We have a small and vibrant design team in Victoria, BC with a collaborative spirit that is both humble and bold. We work together to navigate all design steps from the whiteboard to fully tested, volume-manufactured products.

We are looking for a fledgling electronics designer – someone with some PCB experience and a hunger to crank this up a few notches. If you:

- have an innate desire to create new things with electronics,

- noodle intently over circuit designs and PCB layouts, and

- yearn to expand your technical depth and understanding,

then you will likely be a great fit!

Will it all be whipped cream and roses? Probably not. But as a team we’ll chip away at this awesome, fun and sometimes infuriating dream that we’ve decided deserves to become a reality.

Qualifications:

- Currently enrolled in an Engineering degree in a related field (EE, Eng Phys, Mechatronics, etc.)

- Strong and growing foundation in electronic and microelectronic theory

- Designed, built and tested a few PCBs so far

- Deep, insatiable impulse to understand, and leverage that understanding to create new things

- Innate desire to collaborate, learn, and adapt

Benefits:

- Paid holidays, Educational reimbursement, Relocation reimbursement

How to Apply:

Please complete our short application and submit your materials. Resume and cover letter are required for consideration. Portfolios are encouraged but not required.

Term: Fall 2025

Start Date: September 2nd, 2025

Deadline to apply: July 31st, 2025

Hours per week: Minimum 40 hours

Duration: 4 or 8 months

Pay rate: $25 CAD – $35 CAD per hour

Location: Victoria, BC

At Blue Robotics, we enable the field of marine robotics with affordable components and systems. What does this really mean? We design cool tech for use underwater that enables tons of people and organizations to pursue their audacious dreams of exploring and learning about our oceans and waterways.

We have a small and vibrant design team in Victoria, BC with a collaborative spirit that is both humble and bold. We work together to navigate all design steps from the whiteboard to fully tested, volume-manufactured products.

We are looking for a fledgling mechanical designer – someone with some CAD experience and a hunger to crank this up a few notches. If you:

- have an innate desire to create new things,

- noodle intently over your projects, and

- yearn to expand your technical depth and understanding,

then you will likely be a great fit!

Will it all be whipped cream and roses? Probably not. But as a team we’ll chip away at this awesome, fun and sometimes infuriating dream that we’ve decided deserves to become a reality. And don’t worry – you won’t get stuck on a manufacturing line – you’ll design real products and you’ll be given the same responsibility as any of our full-time engineers.

Responsibilities

- Design new and complex mechanical assemblies, such as pressure-rated enclosures, brushless motors, battery modules, connectors, lights, electronics trays, cameras, and vehicle frames

- Evaluate system failure modes, create validation plans and support the execution of these plans

- Component and vehicle-level testing for performance, durability, reliability, and variability

- Design new lab testing equipment and perform lab testing

- Find, communicate with, and build relationships with new suppliers

Basic Qualifications:

- Currently enrolled in an Engineering degree in a related field (Mechanical Engineering, Eng Phys, Mechatronics, etc.)

- Proficiency in 3D modeling and drafting of components and assemblies in at least one CAD software package (Solidworks, NX, CATIA, Inventor, Fusion, Onshape, etc)

- Strong and growing foundation in statics, dynamics, thermodynamics, and engineering materials

- Designed, built, and tested some interesting things so far

- Deep, insatiable impulse to understand, and leverage that understanding to create new things

- Innate desire to collaborate, learn, and adapt

Benefits:

- Paid holidays, Educational reimbursement, Relocation reimbursement

How to Apply:

To apply for this position, please follow the link to complete a short application and submit a project portfolio, resume, and a brief cover letter. Project portfolios are accepted in any format (website, document, presentation, github, etc) – send us your solid models and assemblies for bonus points!

Future Opportunities

Interested in a career at Blue Robotics but don't see a good fit at this time? Add your contact information and some positions you'd be interested in below and we will reach out if something opens up!

"*" indicates required fields