Quality

We’re on a mission to enable the future of marine robotics by designing and manufacturing low-cost, high-performance components because we believe marine robotics should be accessible to everyone.

While a main focus of ours is quality, we have to be honest, high volume manufacturing is hard! We do our best to build products you are satisfied with and we’d love to let you in on our process of where we do things, how we do them, and why it’s difficult.

As you can probably tell, we’re big water people, but our operations are obviously on land. And while we have teammates, partners, and customers all over the world, we decided that sunny southern California was the perfect spot for our home base.

If you’re interested in seeing where the manufacturing magic happens, take a virtual tour of our warehouse!

Building low-cost, high-quality products with consistent quality is hard! There’s a whole team of people working every day to make sure that every product you receive is impeccable.

The ocean is a tough place and our product designs have to be equally prepared to brave the freezing arctic and a hot, sunny day at the equator. They have to be unquestionably reliable under figurative and literal pressure and they have to be easy and fun to use. But before they even hit the water, we have to build them here!

That requires managing an inventory of over 1,500 different raw parts from nearly a hundred different suppliers around the world, fine tuning the production line and process for each product, training and taking care of our assembly team, and ensuring quality throughout! It takes a wide range of humans with roles ranging from Assembly Technician to Purchaser to Manufacturing Engineer to Production Manager to accomplish that.

When issues occur, and they inevitably do, we have to act fast to fix them and make sure we take care of any customers who might have been affected! Have something to report? Get in touch – we are here to help!

Our design engineering team spends countless hours coming up with innovative designs and testing them like crazy to make sure they always work. We’ve built specialized equipment to subject our products to extremes of pressure, temperature, time, and heavy usage. We test tens to hundreds of units and put them through hundreds of usage cycles.

We have a clear development process to make sure that happens every time for hundreds of product developments.

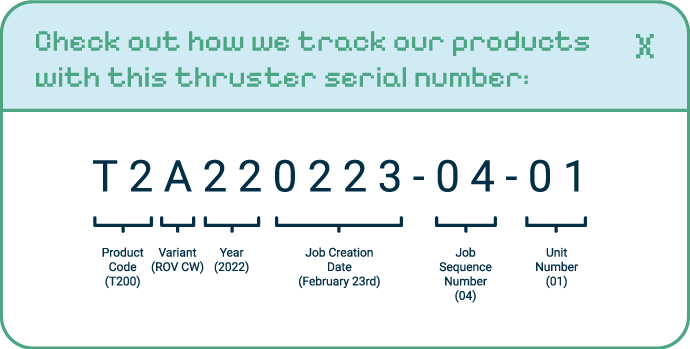

In production, we maintain tight control over our raw materials and process to make sure every product is as close to perfect as it can be. We conduct incoming inspections on raw materials, in-process quality checks, end-of-line performance testing, all logged with the unit’s serial number for traceability.

We have an amazing production team, equipped with the best tools for the job. They stay up-to-date on the constantly evolving process and know how to handle curveballs along the way.

We’re always striving to improve and to deliver the highest consistency and quality so our customers can continue to change the world of marine robotics.