Specifications

*Values limited by ESC used to drive thruster.

Note that nominal operation at 12-16 V is recommended for the best balance of thrust and efficiency, though operation at up to 20 V is allowable. Exceeding 20 V is not within the rating and not recommended, please see here for more information.

For more detailed performance specifications, including thrust, RPM, power, and efficiency at various throttle levels and supply voltages from 10-20 V, please see the performance charts below.

Performance Charts

Click on the legend to hide or show the data set for each voltage. All the raw data and notes on the testing procedure used to generate these charts can be downloaded here:

T200-Public-Performance-Data-10-20V-September-2019 (.xlsx)

T200 Thruster Performance

Thrust at 10-20 V

Current Draw at 10-20 V

Efficiency at 10-20 V

Thrust and Power at 10-20 V

RPM at 10-20 V

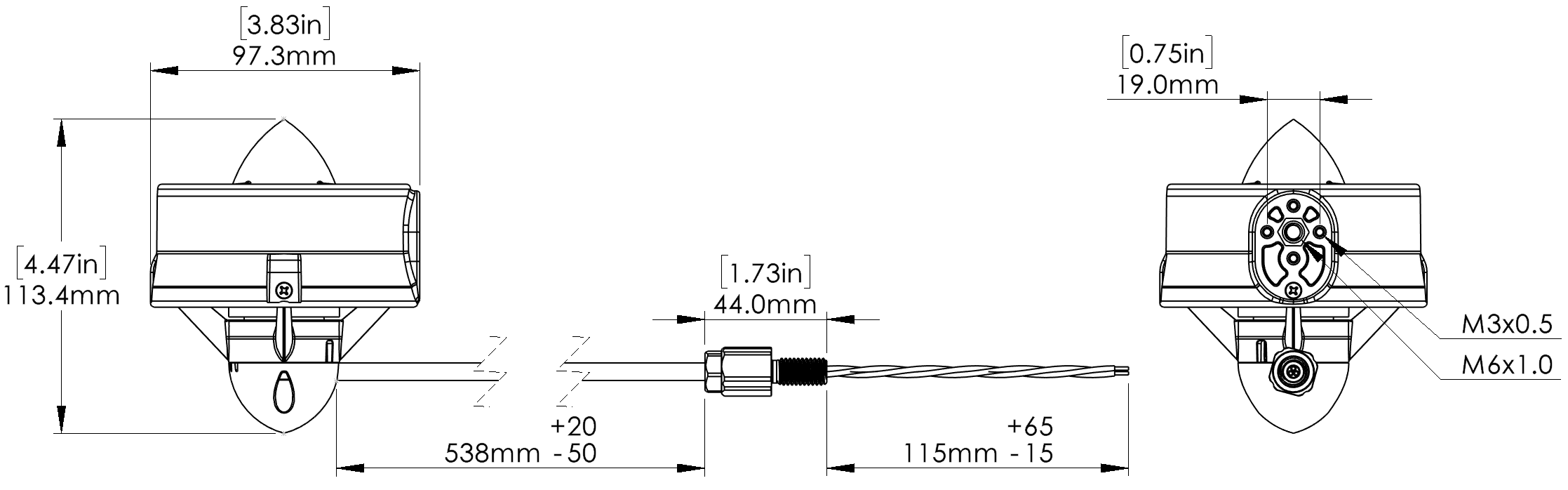

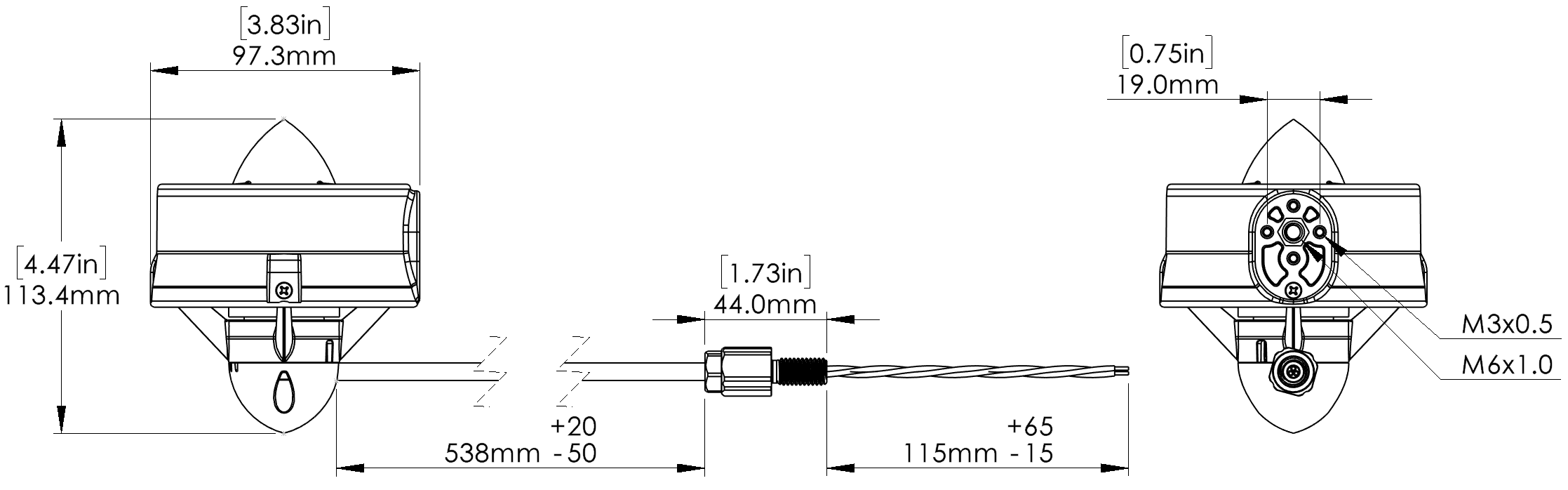

2D Drawings

3D Models

T200_THRUSTER_BR-100545_BR-100228 (.zip)

Revision History

14 January 2025

- BR-100228-001, Clockwise

- Added M6 threaded insert for single fastener mounting

9 December 2024

- BR-100228-002, Counterclockwise

- Added M6 threaded insert for single fastener mounting

21 May 2024

- Nose cone, nozzle, and propeller material changed to 10% glass-filled polycarbonate

14 March 2023

- Serial number laser marking implemented

24 May 2021

- R2 – Initial release

- Updated pre-installed penetrators to compression gland penetrators

07 July 2020

- Changed SKU from T200-THRUSTER-BROV2-SPARE-R1-RP to T200-THRUSTER-BROV2-SPARE-R1-VP so CW and CCW variations may be ordered. The opposite spare propeller is still included.

08 November 2019

- Changed stator from being epoxy coated to fully potted

- Added cooling holes to propellers

15 September 2019

- Changed finish of polycarbonate components from glossy to matte

19 September 2014