These 3″ and 4″ locking tubes are available in a variety of lengths in anodized 6061-T6 aluminum. These tubes are a substantial upgrade over the first generation of watertight enclosure tubes.

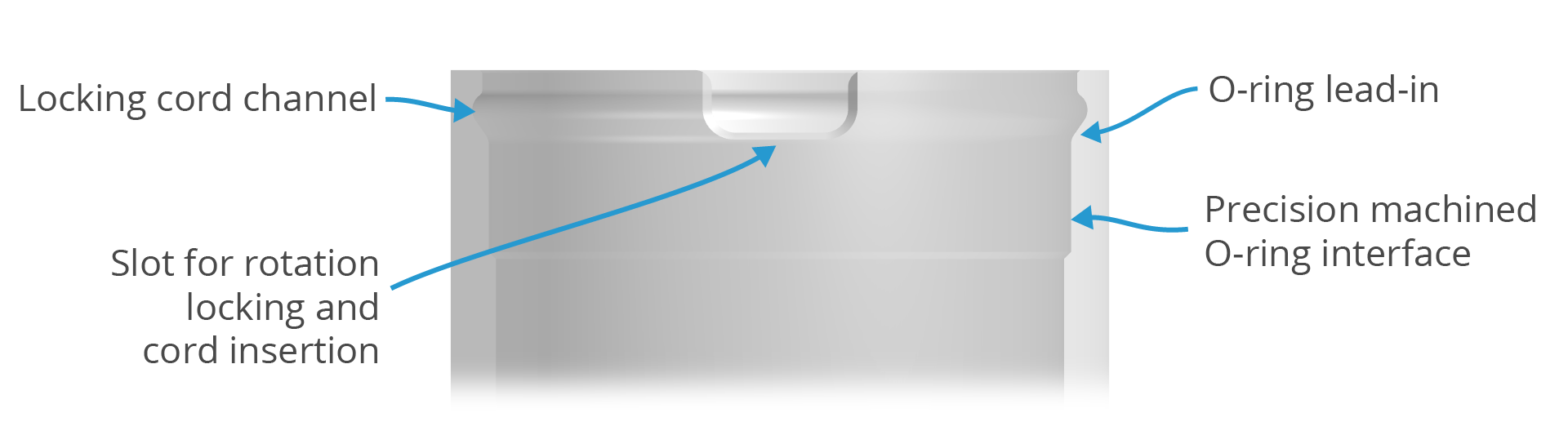

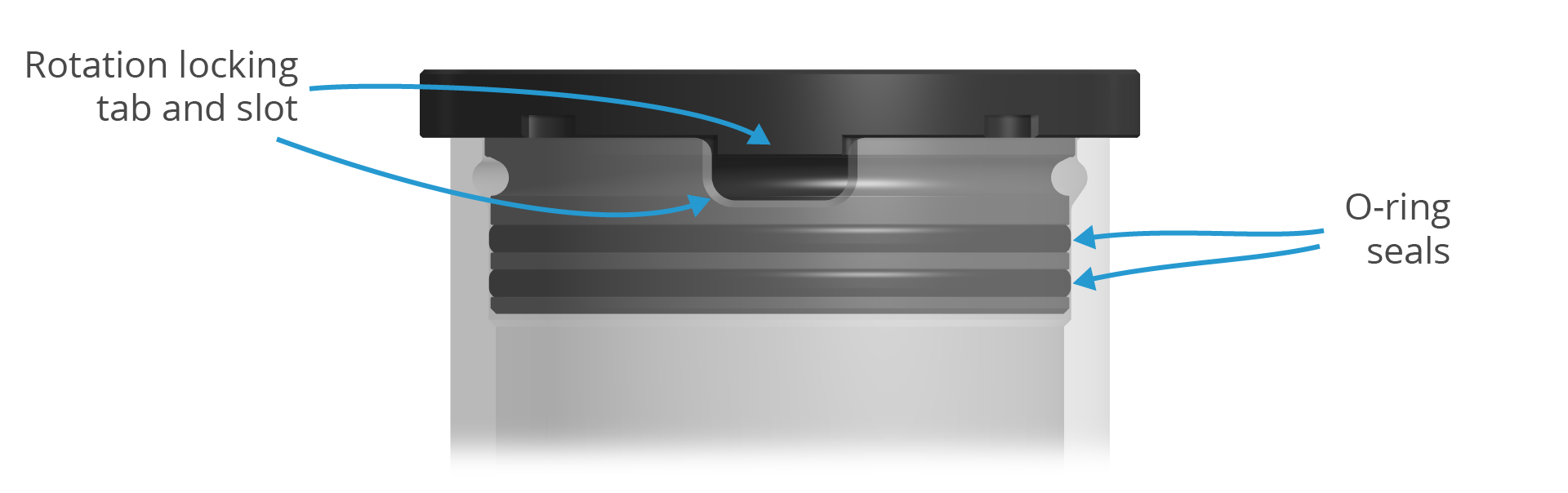

Both the acrylic and aluminum tube options have precision machined O-ring interfaces at each end, ensuring a consistent and reliable fit with the sealing flange. A smooth surface finish ensures proper sealing between the O-ring flange and the tube. Also machined into the ends is a gland for a locking cord and a slot for cord insertion. You can read more about the locking feature and see a diagram of how it works on the main watertight enclosure product page.

The slot for cord insertion doubles as an anti-rotation feature, mating with a feature on the flange. This keeps the flange in a consistent orientation with the tube and prevents the user from rotating the flange and damaging anything inside the enclosure.

The tubes are available individually here, but you can configure a complete watertight enclosure from the watertight enclosure configuration page.

Because of the precision machined interface, the tubes are no longer available in custom lengths.