M200 Motor User Guide

Introduction

The M200 Motor is a subsea motor designed to run in harsh ocean conditions, making it perfect for use on USVs (like the BlueBoat), AUVs, and in custom projects such as actuators and subsea tooling. This guide explains how to use and service the M200 Motor.

Important Safety Notes

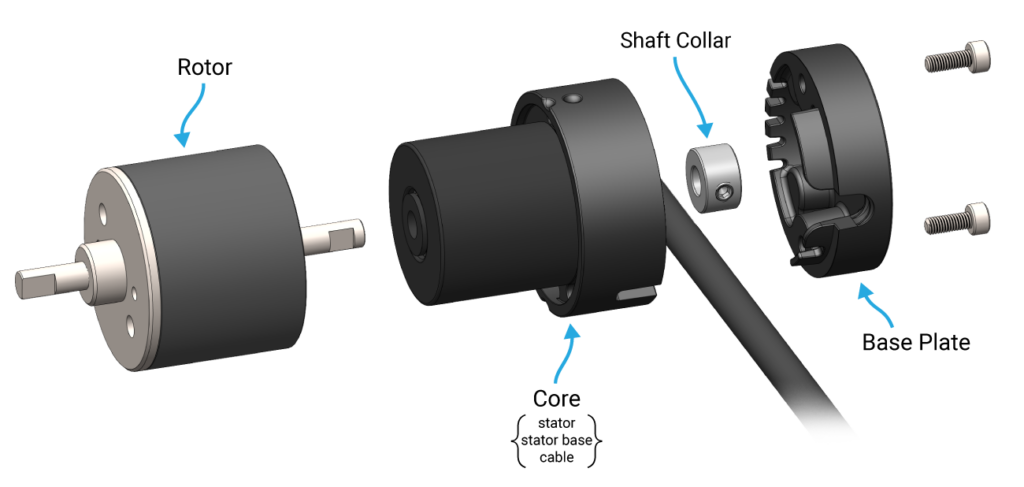

Parts of a Motor

The M200 is an outrunner motor. When actuated, the entire rotor spins while the rest of the motor components remain stationary. The following diagram shows the components of an M200 Motor.

Rotor Attachments

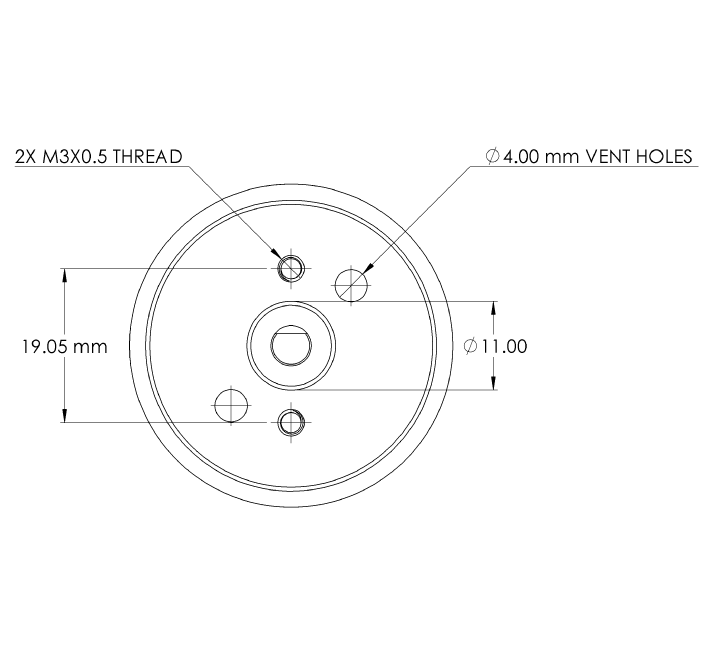

The top of the rotor has two M3x0.5 threaded holes that can be used to attach components. The screw thread engagement for these holes should not exceed 6 mm. The two larger, unthreaded holes are for drainage.

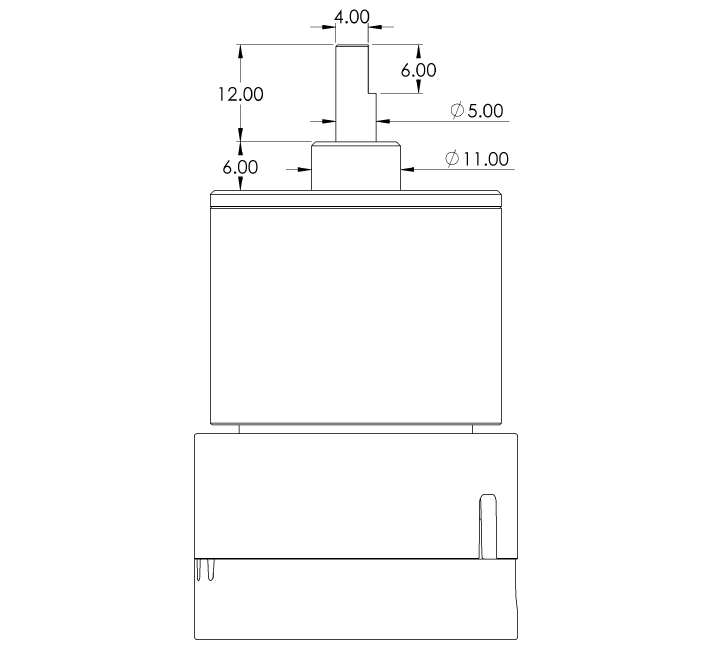

The end of the rotor shaft has a drive flat. The flat area of the shaft provides a flat surface for a fastener and prevents slippage of an attached component.

The Blue Robotics Weedless Propeller and the T200 Propeller are both compatible with the M200. These should be installed on the rotor using the M3x0.5 mounting holes.

Operation

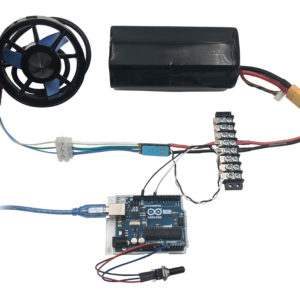

To operate a motor you need:

- The motor

- A brushless electronic speed controller (ESC)

- A power source

- A signal to control the ESC

Each of these components is essential to operating the motor.

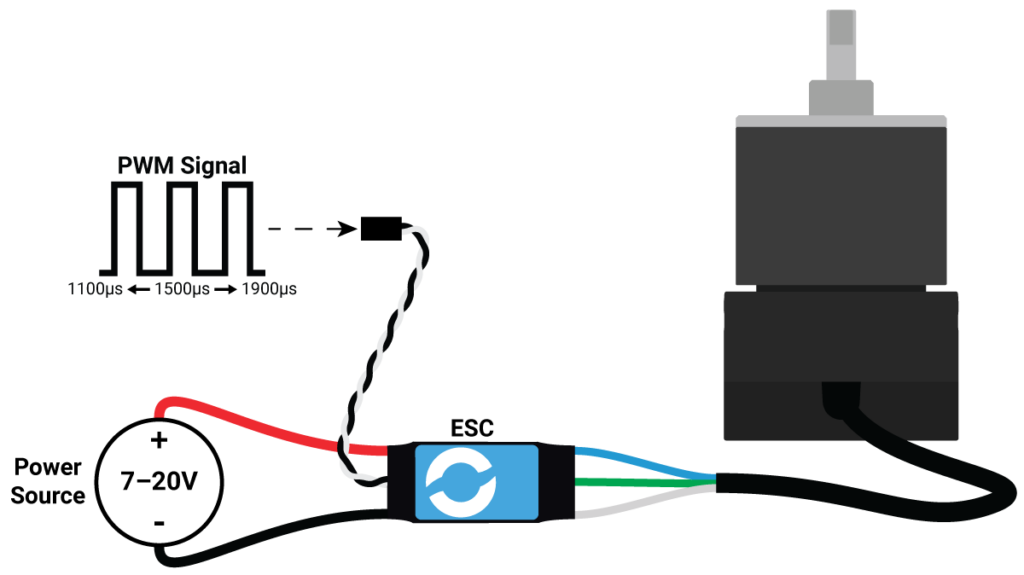

The following diagram shows how everything is connected:

1. Connecting to an ESC

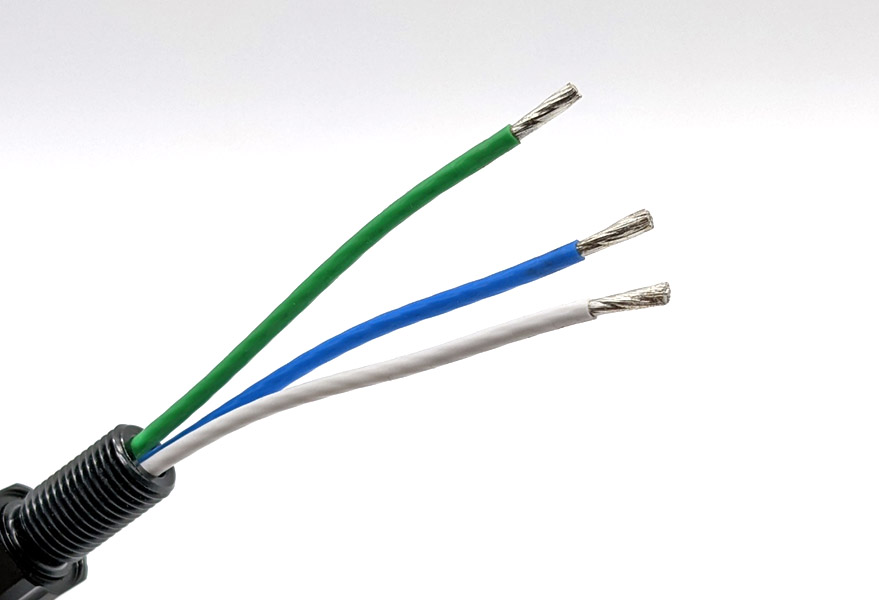

The M200 cable has three conductors that terminate in tinned wire ends.

Connect these three wires to the three motor phase wires from the ESC. How you connect the wires is up to your preference. The wires can be soldered together or you can use connectors like bullet connectors or screw terminal blocks. The order does not matter, the motor will spin with the wires connected in any configuration. If the motor is spinning in reverse of what is desired, swap the connection of two of the wires.

2. Connecting to a Power Source

After the motor is connected to the ESC, connect the red (positive) and black (ground) ESC power wires to a power source. The power source voltage should be within the 7–20 V operating voltage range for the M200.

When the ESC is connected to power you should hear three beeps in rising pitch indicating the ESC is receiving power.

3. Sending the Signal

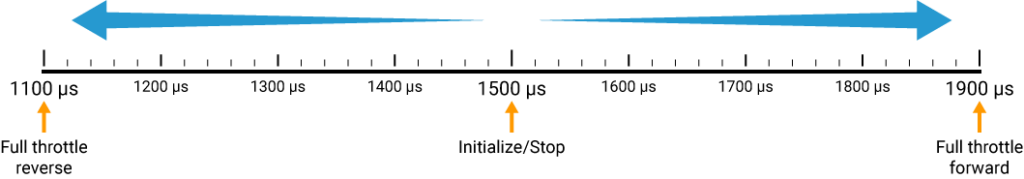

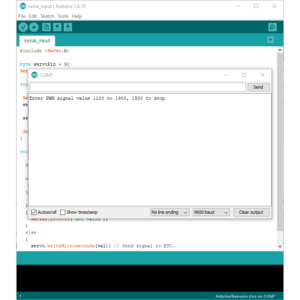

Connect the white ESC signal wire to the signal source output. Connect the black (ground) ESC wire to a ground pin on the signal source device. Send a PWM signal of 1500 microseconds (µs) to initialize the ESC. The ESC must be initialized before it will respond to any other throttle signals. When the ESC is initialized you should hear two more beeps. The first beep indicates the ESC detects a throttle signal and the second beep indicates that the correct 1500 µs signal is detected and the ESC is now fully initialized.

After the ESC is initialized, sending a PWM signal from 1100 µs to 1900 µs will control the speed and direction of the motor:

- 1500 µs to stop the motor

- >1525 µs to 1900 µs for forward

- <1475 µs to 1100 µs for reverse

While testing your motor, do not operate it at high speed for more than 10 seconds outside of water (while dry) at a time. The bearings require water for lubrication and may be damaged if the motor is operated for an extended period of time while dry. You may also notice a clicking noise or that some motors are noisier than others. This is normal. Because of the tolerances of the plastic bearings and the metal rotor shafts, the rotor shaft can move slightly in the bearing causing variation in how different motors sound. Any noise is significantly reduced or eliminated when operated in water.

If you are having problems with motor operation please refer to the Troubleshooting section of this guide.

What kind of device can be used as a signal source?

Pretty much anything that can output the correct PWM signal! The PWM signals used by the ESC are the same signals commonly used by RC receivers or to control servos. The following are a few examples of devices that can be used as a PWM signal source:

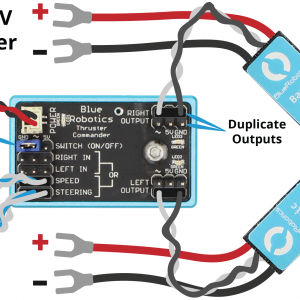

Blue Robotics Thruster Commander

The Thruster Commander is a great way to get started using our motors. We recommend it for first-time users and anyone who is not sure about what signal source they should use.

Guide:

Guide to the Thruster Commander

Flight control devices like the Navigator Flight Controller or Pixhawk Autopilots

These devices are used to control unmanned vehicles like ROVs, AUVs, USVs, etc.

Arduinos, Raspberry Pis, and other types of microcontrollers and SBCs

These can be used for a multitude of DIY projects, from human-operated vehicles to fully autonomous vehicles.

Guide:

Control the Basic ESC with the Arduino Serial Monitor

Control the Basic ESC with a Potentiometer and Arduino

RC transmitters/receivers

These are a good choice for adding simple wireless controls to a vehicle. Just remember, they don’t work underwater!

Guide:

Control the Basic ESC with an RC Transmitter

Simple Servo testers

Probably the most simple type of signal source. Servo testers work well for testing motors (go figure) or as a super simple, single-input control method.

Motor Mounting

The M200 Motor can be mounted in two ways.

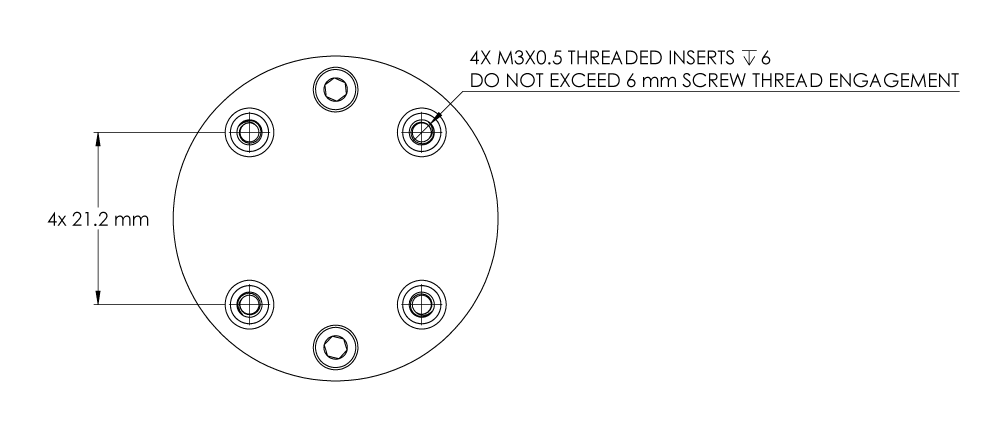

Base Plate Mounting

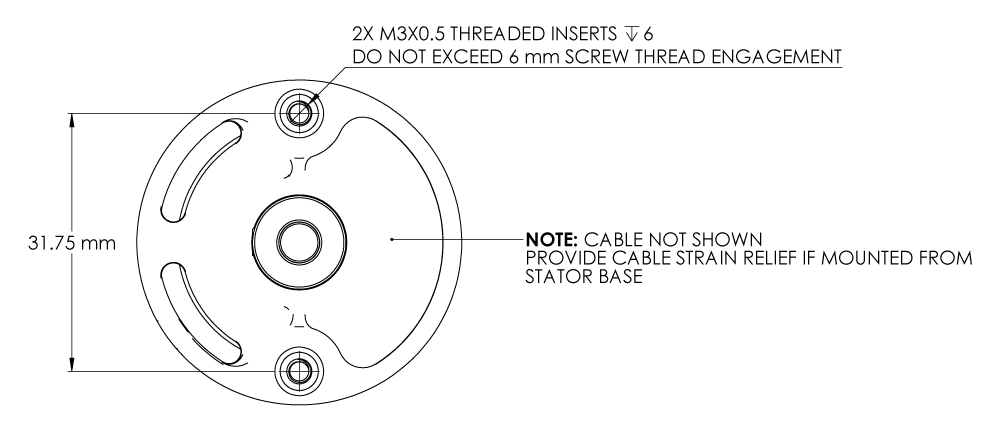

The M200 can be mounted from the base plate using the four M3x0.5 threaded inserts. The screw thread engagement for these mounting holes should not exceed 6 mm. The mounting hole pattern is provide below.

Stator Base Mounting

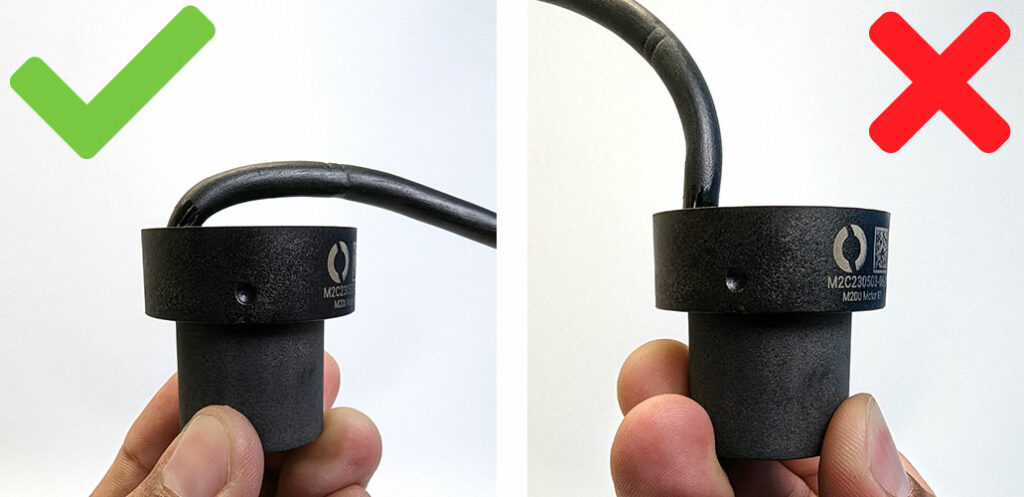

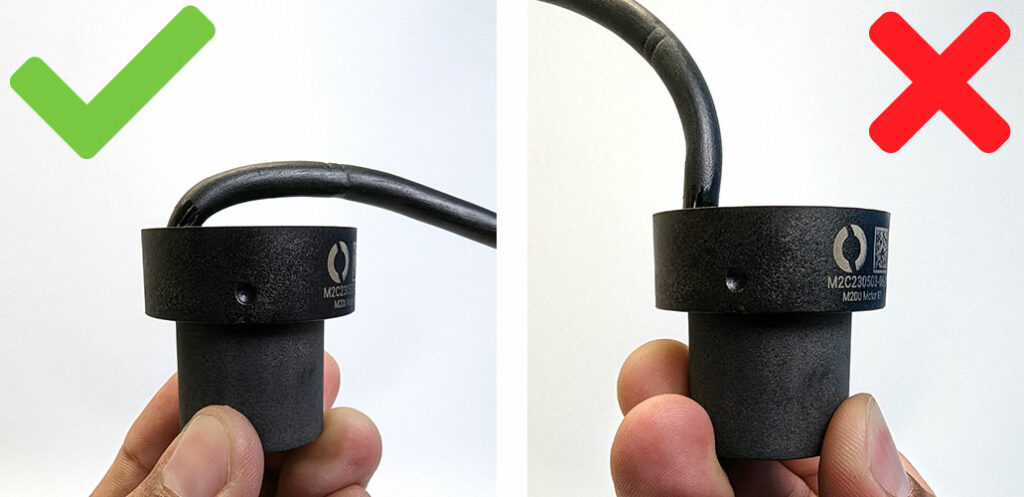

The base plate can be removed and the motor mounted directly from the stator base using the two M3x0.5 threaded inserts. The screw thread engagement for these mounting holes should not exceed 6 mm. If mounted from the base plate, provide strain relief for the cable and maintain the cable bend direction. Do not bend or strain the cable in the other direction. Straining the epoxy joint will compromise the depth rating of the motor.

M200 Tools

Refer to the table below for tool and screw sizes.

| Screw Size | Tool | |

|---|---|---|

| Base plate screws | M3x8 mm socket head cap | 2.5 mm Hex |

| Shaft collar set screw | M4x4 mm set screw | 2.0 mm Hex |

M200 Disassembly and Reassembly

You may have to disassemble your motor occasionally for cleaning and maintenance. Follow the instructions below to disassemble your motor.

1. Use a 2.5 mm hex driver to remove the two base plate screws.

2. Remove the base plate. Take notice of how the motor cable bends and exits the base plate. It is important to maintain this cable bend direction. Do not bend or strain the cable in the other direction. Straining the epoxy joint will compromise the depth rating of the motor.

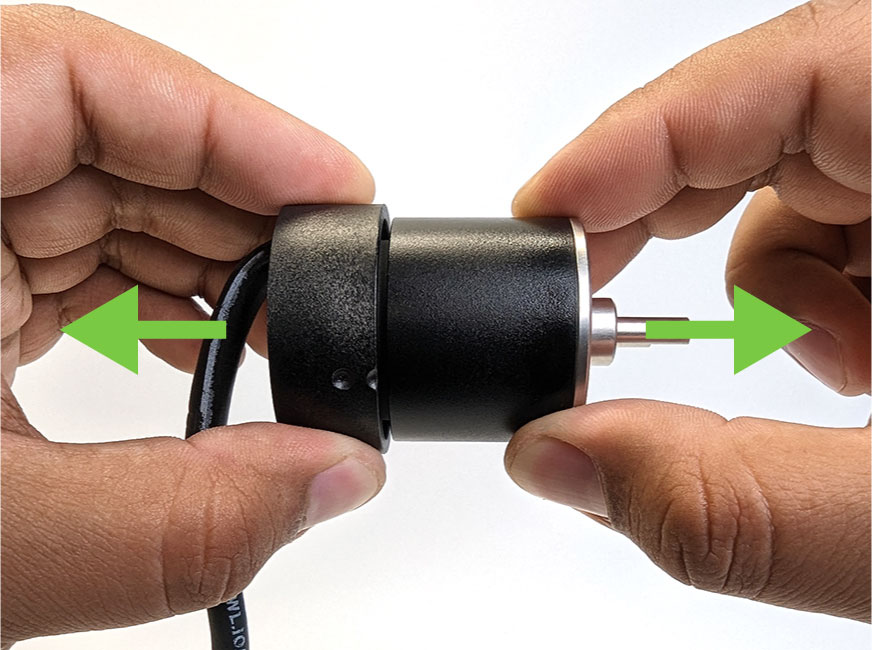

3. Rotate the rotor by hand until the shaft collar set screw lines up with the notch in the stator base. Use a 2 mm hex driver to loosen the set screw.

4. Do not pry up on the shaft collar to remove it. Instead, pull the rotor away from the motor core to separate it from the stator.

The motor is now disassembled.

Reassembly

1. Ensure the shaft collar is in the stator base then install the rotor onto the motor core.

2. Use a 2 mm hex driver to tighten the shaft collar set screw onto the flat side of the rotor shaft.

3. Install the base plate onto the stator base. Make sure to maintain the natural cable bend direction. Do not bend or strain the cable in the other direction.

Care and Maintenance

After Every Use

- Rinse with fresh water after use in saltwater to minimize the accumulation of salt deposits.

- Rinse with fresh water after use in sandy or sediment-heavy environments.

Every Five to Ten Uses

- Inspect the inside of the rotors and remove any buildup.

- Inspect the cable jacket for tears or damage.

Troubleshooting

ESC Beeps

When a motor is connected to an ESC, the ESC can use it as a “speaker” to play a series of beeps. These beeps provide information about the status of the ESC and are useful for troubleshooting. The following is the meaning of the beeps played during the typical initialization sequence.

1. At power on the ESC will beep three times in rising pitch. If you do not hear these beeps:

- The ESC may not be receiving power. Check your power supply and all power connections.

- The thruster may not be connected correctly to the ESC. Check that there is a good connection between the three ESC wires and the motor wires.

- The ESC may be defective.

2. If any throttle signal is detected the ESC will then beep one time. If you do not hear this beep:

- It means the ESC is not receiving any sort of throttle signal. Check the signal source to see if it is powered on and sending the correct signal.

- Check the connection between the signal source and the white ESC signal wire.

3. If the initialize/stop signal (1500 µs) is detected the ESC will beep one final time indicating that it is fully initialized. If you do not hear this beep:

- It means the ESC is not receiving the correct 1500 µs signal. Check if your signal source is sending the correct 1500 µs signal.

The motor does not spin or move at all

- This is usually an issue with the improper operation of the ESC. Refer to the ESC Beeps section above to troubleshoot the ESC.

The rotor tries to move but does not spin correctly

- All three motor wires may not be connected to the ESC wires correctly. Check that there is a good connection between the three ESC wires and the motor wires.

- There may be a broken motor wire or a short between wires. Check the resistance of each motor wire pair (blue wire/green wire, blue wire/white wire, green wire/white wire) using a multimeter. Each wire pair should have the same resistance within 0.1-0.2ohms or so. If there is no continuity between a pair, or one pair has significantly higher resistance, the thruster is defective.

- Try to rotate the rotor by hand, it should spin freely. If it is difficult to rotate, disassemble the motor and check for damage or blockage.

The rotor is jammed and cannot be turned by hand

- This can be caused by something jamming the rotor or by major internal damage caused by overheating, short circuits, heavily worn bearings, etc. Completely disassemble the motor and inspect for damage or blockage.

Swap-Components Troubleshooting

A great way to troubleshoot a problem is to swap components with other known-working components and observe whether the problem stays in place or moves with the component. To troubleshoot a motor using this method you will need an different motor and ESC set that you have confirmed is working normally.

1. Swap the problematic motor with a motor that you know works well. That is, connect the problematic motor to the ESC that was connected to the working motor and connect the working motor to the ESC that was connected to the problematic motor. If the problem follows the motor, you know that the motor is defective. If the problem stays with the ESC, move on to the next step.

2. Swap the signal sources of the ESCs. If the problem follows the problematic ESC, you know the ESC is defective. If the problem stays with the signal source, then there is a problem with the signal source.

Feedback

We’re always trying to make our documentation, instructions, software, and user experience better. If you’d like to leave feedback about how we can make this guide better, let us know here.